Cleanrooms are highly-controlled environments where pollutants and particles are filtered out to keep the room as clean as possible.

Did you know some cleanrooms are clean enough to protect objects that wind up in space? We’ll dive into some fun facts on the rarest cleanroom type (ISO 1 cleanroom) toward the end of this overview.

How Do Cleanrooms Work?

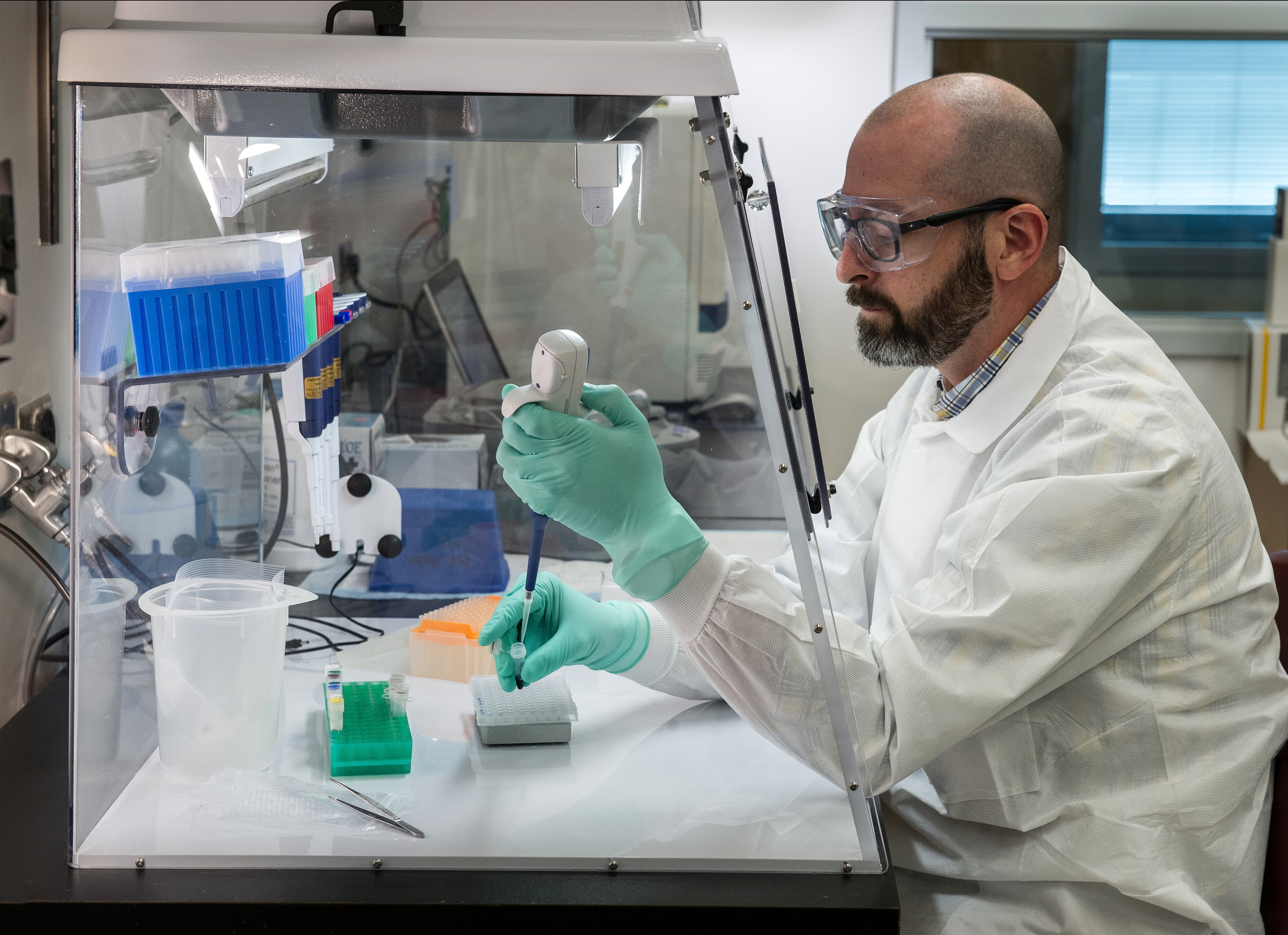

Any process at risk of being affected by contaminants or particles in the air can benefit from a cleanroom. You might find cleanrooms for use in fields like medicine, research, pharmaceutical, and nanotechnology.

Cleanrooms include filters that remove pollutants, particles, and contaminants from outside ambient air. Depending on the cleanroom type, the filtered air is either recirculated or forced outside the room.

Depending on the task, a cleanroom may require little filtering or extremely powerful filtering that can remove the tiniest particles imaginable.

In addition to filtering particulates, cleanrooms regulate several other properties:

- Temperature

- Humidity

- Airflow

- Filtration

- Pressure

Cleanroom ISO Classifications

The International Organization for Standardization (ISO) maintains agreed-upon standards set by experts in various fields. ISO describes an ISO standard as a “formula that describes the best way of doing something.”

ISO standards cover an enormous range of activities, including using cleanrooms in ISO Standard 14644-1.

Every cleanroom is classified by an ISO rating that dictates just how clean it needs to be to remain compliant with the requirements of one of nine ISO classifications.

ISO classifies cleanrooms by the number of contaminants present per cubic meter. Classifications range from ISO Class 1, the “cleanest” cleanroom, to ISO Class 9, the “dirtiest.” Each ISO class requires the facility to provide a specific level of filtering.

We’ve created a free cleanroom cleaning guide to help you implement a cleaning process that is safe, repeatable, and scalable. You can download it here >>

Deep Dive: ISO Class 1 Cleanrooms

It’s not an exaggeration to say ISO 1 cleanrooms belong to a very exclusive club. Few Class 1 facilities exist throughout the world. When an organization builds a new ISO 1 cleanroom, it can even make the news.

ISO 1 cleanrooms are appropriate for highly specialized tasks that require absolutely pristine conditions. For example, the European Space Agency uses a cleanroom rated at ISO 1 for procedures like examining temperature sensors destined for the surface of Mars.

You will most likely find Class 1 cleanrooms in the life sciences industry and electronics requiring nanotechnology or ultra-fine particulate processing.

ISO 1 Cleanroom Requirements and Standards

Cleanrooms must meet rigorous requirements and standards to comply with ISO 1.

Essentially, they must be capable of rigorous filtration. ISO 1 cleanrooms must handle 500 to 750 air changes per hour.

ISO 1 cleanroom standards require filtering particulates smaller than a speck of dust. To meet this strict requirement, the air inside an ISO Class 1 cleanroom must test at fewer than 12 particles larger than 0.3 microns or smaller in each cubic meter.

How small are 0.3 microns?

Consider this: On average, a human hair is about 75 microns across. The human eye can’t see particles smaller than 10 microns. It’s hard to imagine how many precautions ISO Cleanroom 1 workers need to take to maintain that level of compliance!

Establishing Cleanroom Cleaning Processes Is Vital

While you may not need to comply with ISO requirements as strictly as an ISO 1 cleanroom, keeping your cleanroom in ISO cleanroom compliance is still crucial.

You run several risks if you don’t establish an ISO-compliant cleaning process that is systematic, repeatable, and consistent:

- Failed audits

- Process failures

- Missing industry regulations

Worst, you can lose your ISO certification, impacting your entire organization. Clients will lose confidence in your products or services. To get your certification back, you’ll have to pause operations, losing more money by the day.

Cleaning a cleanroom is unlike other cleaning processes. Your employees and janitorial staff do not have the specialized training and equipment to maintain a cleanroom.

Ready to get assistance with your cleanroom cleaning? Receive your instant quote today!