Not all cleanrooms are created equally. There are several different classifications for cleanrooms, and each comes with its own standards and regulations. The International Standards Organization (ISO) governs these classifications according to particulate cleanliness. In a nutshell, ISO cleanroom classifications let you know how many particles you’re allowed to have in the cleanroom.

About The Pegasus Team

The Pegasus Team's Recent Posts

A Breakdown of the ISO Cleanroom Classifications and What They Mean to You

Nov 16, 2018 7:00:00 AM / by The Pegasus Team posted in Insider, Cleanroom

Cleanroom Protocols You Need to Establish and Follow for Success

Nov 2, 2018 7:00:00 AM / by The Pegasus Team posted in Insider, Cleanroom

Establishing and adhering to cleanroom protocol is important to keep the integrity of your cleanroom intact. Contaminants can be introduced from a variety of sources, but the most detrimental source of contamination comes from the humans that occupy your cleanroom. The greatest and most affordable resource for keeping those contaminants at bay is ensuring proper protocols are in place.

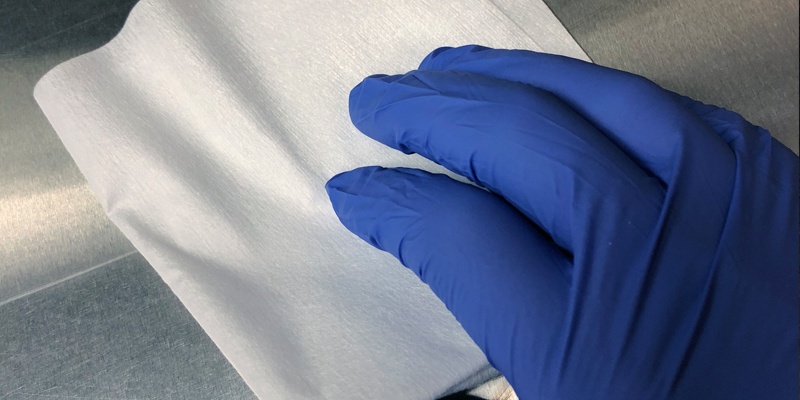

Everything You Need to Know About Cleanroom Wipes

Oct 26, 2018 7:00:00 AM / by The Pegasus Team posted in Insider, Cleanroom

It is critically important to use the correct wipes when cleaning your cleanroom. If you are not using the correct cleanroom wipes (also commonly referred to as “wipers”) you are not cleaning your cleanroom properly. When you do not clean your cleanroom properly, you run several risks that can affect your business, products, and customers. In addition, using a wiper that is too clean for your needs can be a costly mistake.

6 of Our Favorite Cleanroom Products

Oct 5, 2018 7:00:00 AM / by The Pegasus Team posted in Insider, Cleanroom

When you’re working in a controlled environment, it’s important to only bring cleanroom-specific products into the area. This includes everything from cleaning supplies to production materials to management tools — even pens and clipboards need to meet cleanroom standards.

Your Cleaning Process Should Be Based on Your Cleanroom Classification

Sep 27, 2018 7:00:00 AM / by The Pegasus Team posted in Cleanroom

Cleanroom classifications are most commonly based on the number of particles of a certain size in a cubic meter of air. They can also be classified according to air cleanliness by chemical concentration and surface cleanliness by particle or chemical concentration.

7 Pharmacy Cleanroom Standards to Protect Your Business & Customers

Sep 13, 2018 7:00:00 AM / by The Pegasus Team

Willis Whitfield invented the cleanroom in 1962. He designed a space that blew filtered air in from above and sucked it out from below, eliminating particles through gravity and replacing all the air in the space in six seconds. The design was so effective Whitfield himself didn’t believe the results. He even understated the numbers shown by particle detectors to avoid shocking listeners. But then a scientist from Bell Labs verified the results were 10 times better than Whitfield was describing.

The Risks You Run Without Proper Cleanroom Cleaning Processes in Place

Sep 7, 2018 3:31:10 PM / by The Pegasus Team posted in Cleanroom

Having a cleanroom cleaning process in place is incredibly important. After all, it’s not much of a cleanroom if it isn’t clean! Beyond that, the state of your working environment impacts all facets of business operations. From your employees to your consumers, from your reputation to your bottom line, proper cleanroom cleaning is of paramount importance for any company that produces products in a controlled environment.

You should not rely on your employees, your janitorial staff, or even a cleaning service to know the nuances and requirements for cleanroom cleaning. You need to have a process in place. Without a proper cleanroom cleaning process, you run the risk of violating the industry’s contamination control, maintenance, and safety regulations.

Furthermore, to increase your employees’ morale and productivity, you need to ensure they are safe and healthy. To limit operational costs, reduce accidents, and minimize product defects. The bottom line is regardless of your business’s revenue; you can’t afford to have anything short of meticulous cleanroom cleaning processes in place.